- SiteMap

- Japanese

TPM(Total Productive Maintenance), is a management system aimed at reducing the losses at the factory to zero,mainly for the equipment management of automated factoryand to maintain productivity.

It is called “Total Productive Maintenance”, or Productive Maintenance for all the employees.

※「TPM」is a Registered trademark proposed by JIPM.

The objective of TPM is to prevent the losses, such as failure,defective products, waste at work, by properly maintaining / improving the factory and equipment constantly.

The characteristic is to focus on the losses, and to target to reduce it to zero.

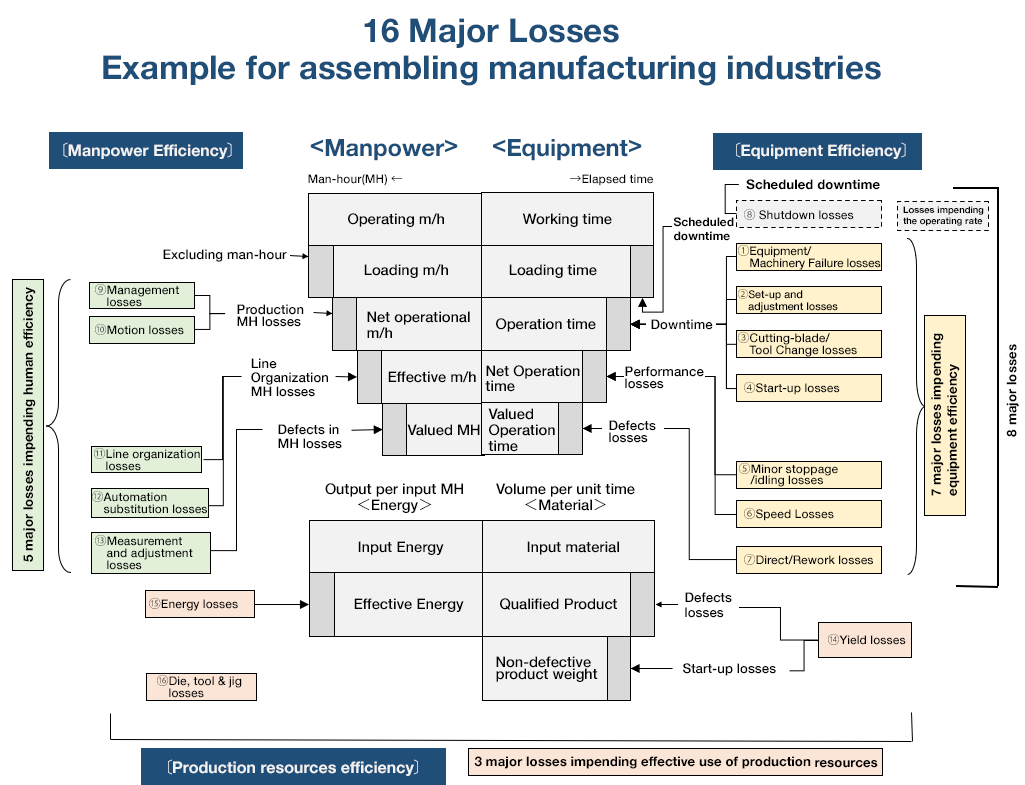

With the concept of TPM, we consider the gap between the ideal operation of the equipment / process, and the current operation, as “the loss”.

To reduce the loss, it is important to clarify the current losses, and to quantify them.

The TPM Activity is conducted by the task-team which consists of the employees from all the sections / functions related to the production, regardless of their occupations (The small-group activity), to reflect on daily condition, and to improve / maintain for elimination / prevention of the losses.

<The 8 pillars>

The pillars (essentials) directly related to the reduction of the loss in the production process. :「Focused Improvement」「Autonomous Maintenance 」「Planned Maintenance」「Quality Management」

The pillars necessary to conduct TPM:「Education and Training」「Safety, Hygiene, Environment 」

The pillars possible to add ・ correct accordingly, depend on the company or factory:「Early Management for Product and Equipment Development」、「Office TPM」

※The pillars are called differently depending on the company, but here is the standard of TPM pillars.

| 【The definition of TPM】 TPM is a holistic approach to equipment maintenance that strives to achieve elimination of the losses, by overlapping small group activities involving all the employees (starting with the production department, including all the departments such as development, selling, management) to the activity. Aiming to build the company constitution that strives to perfectionize(overall efficiency)efficiency of the production system. Targeting the life cycle of the production system, building on site the mechanism to prevent losses such as “zero accident・zero deficit・zero failure”. |

TPM Award is a commendation system from JIPM, to commend companies and plants which had excellent results through the TPM activity.

So far, about 4000 plants from about 60 countries have received the award.

TPM is applied in many companies from the world. After this expanding, Japanese Industrial Standards(JIS Z8141:2001)has defined TPM. And now IATF16949:2016(※1)that is an innternational standard, is requiring to build TPM as a system.

In july 2022, PAS1918(PAS=Publicly Available Specification)related to TPM was published by British Standards Institution (BST).

(JIPM was involved in the planning / development)

As PAS1918, we are providing the guidance related to TPM for the equipment / plants of the manufacturing industry, and it is concerning basic points of TPM indicated in IATF16949.

For the TPM activity, we set KPI(Key Performance Indicator)and KAI(Key Activity Indicator)and record them to clarify the losses, results of the activity, and to grasp the progress. As a result, not only the change of KPI over the years, but also the comparison with the similar plant will be possible.

To set the KPI, we have to consider KMI(Key Management Indicator)depending on the purpose of introducing TPM, producing style, products, and strategy of the company.

Overall Equipment Efficiency (OEE) is a representative indicator (KPI) related to the Equipment Maintenance(Equipment Efficiency)mainly based on automated lines.

This is a indicator originally created by JIPM in the process of developing / disseminating TPM, and now OEE is applied in many companies internationally regardless the introduction of TPM. It is mentioned on the IATF16949 and the ISO22400-2:2014 as well.

The collection of the information related to the equipment and operation became easier after the development of the Digital transformation(DX). As a result, the importance of the indicator to measure / evaluate (visualize) the efficiency of the overall production line is increasing.

By adopting OEE, we can find the losses in a wider point of views, and as a result, improving and identifying issues will be possible.

MTBF(Mean Time Between Failures) and MTTR(Mean Time To Repair) are also representative indicators (KPI) related to equipment maintenance such as OEE.

It is stipulated by JIS Z8141 and IATF16949 (above-mentioned) and it is frequently utilized in the manufacturing industry inside and outside of Japan.

MTBF is an indicator to measure the frequency of the failure. It measures “the average interval time between a failure to the next failure” and it shows reliability (Durability) of the equipment,

MTTR is the average time of repair. It shows the maintainability, and it is an indicator to measure ”the average time between the failure and the repair”.

※「TPM」is a Registered trademark proposed by JIPM.