Owens Corning Fiberglass A.S. LTDA TF Plant

| year | category | company | plant | area | industry | movie |

| 2020 | Category B | Owens Corning Fiberglass A.S. LTDA | TF Plant | Brazil | – | – |

Index.

1. Organization Profile

1.1 Company File

Owens Corning (NYSE: OC) is a leading global producer of residential and commercial building materials, glass-fiber reinforcements and engineered materials for composite systems. The first, historic step occurred on Oct. 31, 1938, when Owens-Illinois and Corning Glass officially spun off and incorporated as Owens-Corning Fiberglas Corp., based in Toledo, Ohio. Over the years, OC innovations have ranged from military uses during World War II and the Fiberglas™ – reinforced 1954 Chevrolet Corvette to the manufacturing of materials for Apollo space suits (1969), for instance.

Owens Corning Headquarters Toledo Ohio – USA

Owens Corning Headquarters Toledo Ohio – USA

Corvette body car made with OC fiberglas

Owens Corning has earned its reputation over more than 77 years as a market-leading innovator of glass-fiber technology by consistently providing new solutions that deliver a strong combination of quality and value to its customers across the world and it has received recognition over the years.

For the 10th year in a row, Owens Corning earned placement in the Dow Jones Sustainability World Index in recognition of its sustainability initiatives.

For the 10th year in a row, Owens Corning earned placement in the Dow Jones Sustainability World Index in recognition of its sustainability initiatives.

The DJSI World Index is based on long-term economic, environmental and social criteria

Owens Corning ranked no. 76 on the magazine’s inaugural list. The analysis measured 2,000 public companies on three areas of corporate responsibility: environment, social and corporate governance

Owens Corning ranked no. 76 on the magazine’s inaugural list. The analysis measured 2,000 public companies on three areas of corporate responsibility: environment, social and corporate governance

Owens Corning ranked No. 1 on the 100 Best Corporate Citizens List for 2020 – the second year in a row OC has earned this honor. The annual list recognizes the standout global environmental, social and governance (ESG) performances of the largest U.S.-based public companies.

Owens Corning was named a 2020 Noteworthy Company by Diversity Inc, an organization that annually ranks U.S. companies for diversity, equity, and inclusion

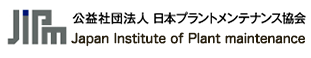

Global Owens Corning Company have three big business divisions:

1.2 Rio Claro Glass Technical Fabrics

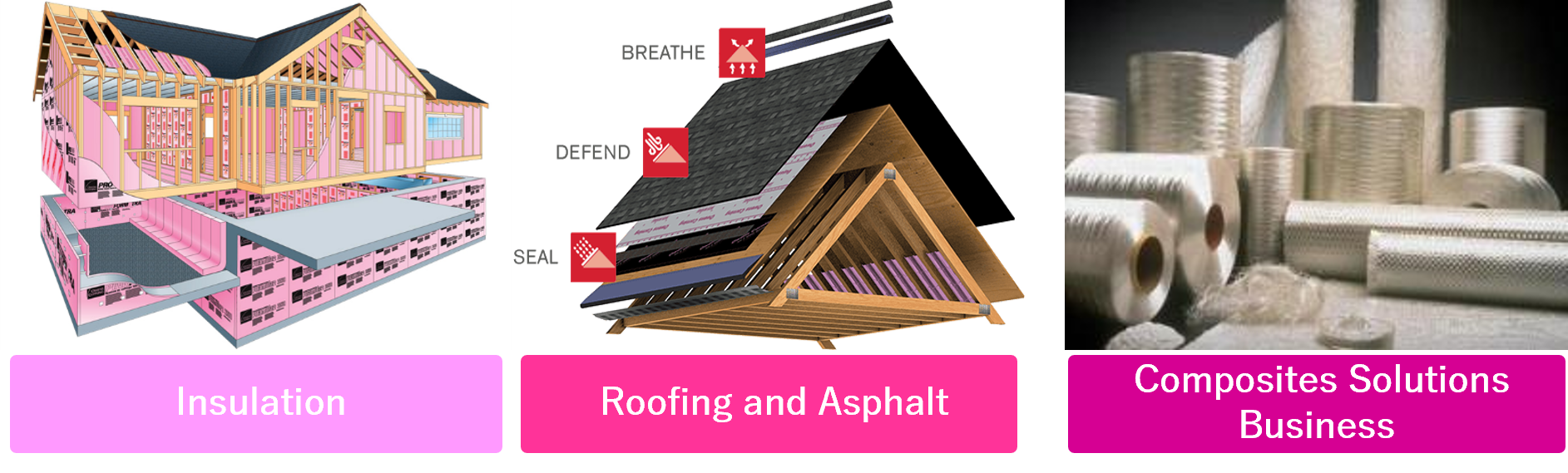

Owens Corning Rio Claro Technical Fabric started its activities in 2008. It’s one of the most strategic Plants of Fabrics of Owens Corning in the world due to its product mix made Rio Claro an important Multi-Category Plant producing Multiaxial, Biaxial and Malimo fiberglass Technical Fabrics.

Owens Corning Rio Claro Technical Fabrics Plant in Rio Claro SP Brazil

Owens Corning Rio Claro Technical Fabrics Plant in Rio Claro SP Brazil

Owens Corning Products and some example of use

2. Milestones on the journey of Manufacturing Excellence

In the Excellence journey phase, TF applied the methodology in its routine to reduce losses and waste in our process. As part of this approach, we have increased the number of employees trained in TPM courses such as Facilitators and Multipliers. Another important activity that we increased too it was the TPM advanced tools use as QC Story, SMED, Infinity Looping and PM Analysis. In addition, we also started a process called “Priority Teams”, where each TPM Pillar is able to deliver main projects that directly touched on the biggest losses in order to improve our results. All of these examples have contributed to Areas transformation , people transformation and strong results. Below are some examples:

Operator demonstrating operating principles to visitors, plant leader and TPM leader

The weekly Kaizen meetings are so that NLT can coach project leaders on the correct application of the methodology

Operator featuring A3 for quality loss reduction

Preparation of OPLs during activities

TPM Multiplier Training

Presentation of Priority Cases

3. Benefits Achieved

3.1 Tangible Results

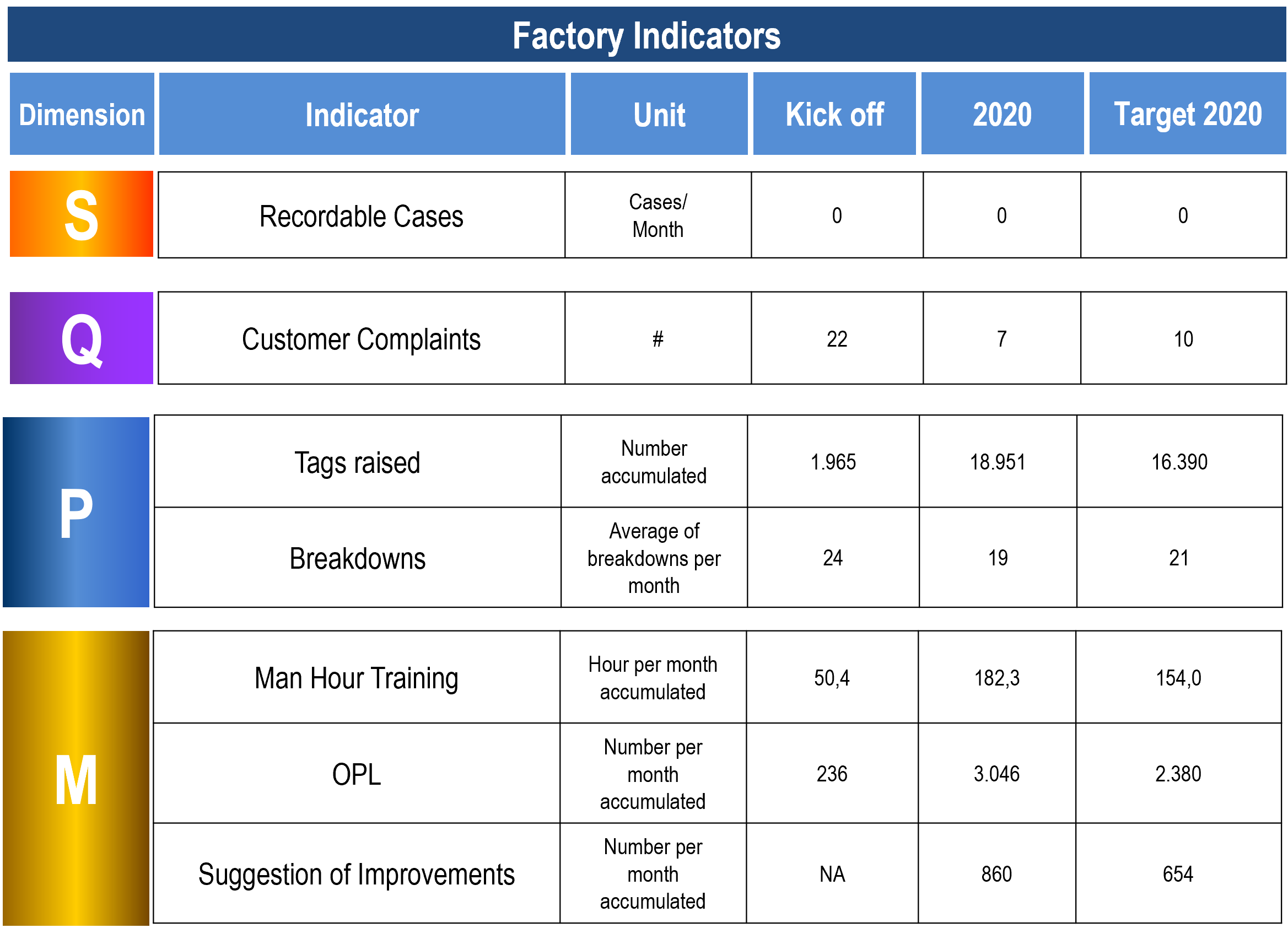

During our Excellence journey, we not only our the results improved, but many Rio Claro TF Plant employees had opportunity to give support to other Plants in their TPM Journey to establish solid processes based on TPM, enhancing the exchange of Best Practices and helping to solidify the culture of TPM at Owens Corning worldwide. A summary of all these benefits and results it’s possible to see in a table below:

3.2 Intangible Results

A important achievement that we had with TPM was people satisfaction to work a better workplace and the feeling that it’s possible to change the status quo. Below we have some milestones:

People Transformation Examples

Pilot Machine Operator presenting his AM routine to the TPM Global Team

Pneumatic module training for the AM Pilot machine team

Operator training other employees in the production appointment process hour by hour

Area Transformation Examples

Operators presenting the cases summary of the work performed during the change audit of the AM stage

Operators showing how to lubricate equipment during AM step change audit

Results Examples

Machine approved in AM Final step change audit

Operator member of the 2019 winning priority case being recognized by the FI pillar

Winning team being recognized during TPM Facilitators CSB training

4. Key of our Manufacturing Excellence

Since we start our TPM Journey, we have learned some things:

1)Support and full participation of Leadership

2)Capacitation of our employees in TPM Methodology and tools

3)Creativity to do a lot of things with less resources

4)Applying the 5G’s:

( Gemba, Gembutsu, Genjitsu, Genri and Gensoku )

5)Mindset to zero losses and wastes

6)Standards preparation

7)People development is fundamental

8)Recognition of achievements

9)Apply TPM as a way of work all the time

Our Vision and next challenges to next Level

-TPM applied to the whole Plant (Supply Chain, Sales, Customer Service, CTSO);

-To continuous improvement in Safety, Quality, Delivery and Costs;

-To strengthen “ZERO CULTURE” to all losses and wastes;

-Continue working for Zero waste to landfill;

-To apply TPM in Suppliers to strengthen our partnership;

-Improve our processes and products to delight our Customers;

-Continuous journey to development Owens Corning people in TPM;

-Continue working to have the Rio Claro Technical Fabrics plant as a TPM reference among the other plants in the World Owens Corning