Zhaodong Yili Dairy Co., Ltd.

| year | category | company | plant | area | industry | movie |

| 2020 | Category A | Zhaodong Yili Dairy Co., Ltd. | – | China | – | – |

Index.

1. Organization Profile

1.1 Yili Group

Yili Group is the largest and most comprehensive dairy company in China in terms of product lines. In the first three quarters of 2020, Yili Group has an operating income of RMB 73.77 billion with a net profit of RMB 6.044 billion, achieving high double growth while setting another new high in the Asian dairy industry. Among them, the core indicators such as total operating income, net profit, comprehensive market share and consumer penetration have been ranked first in Asia, and the ROE continues to lead the Asian dairy industry.

1.2 Plant Overview

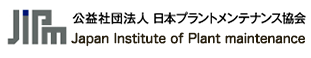

1.2.1 Brief History of Zhaodong Yili

Zhaodong Yili is one of the branches of the Yili Group Liquid Milk Division. It is located in Zhaodong City, southwestern Heilongjiang Province. It covers an area of 200,000 square meters, with a cumulative investment of RMB910 million yuan, and is the largest plant in terms of production capacity in the three northeastern provinces. Zhaodong Yili was put into operation in 2006 and TPM was officially introduced in 2015. Each pillar was introduced one after another at the same time. Through TPM activities, we have achieved steady improvement in performance and improved employeemorale.

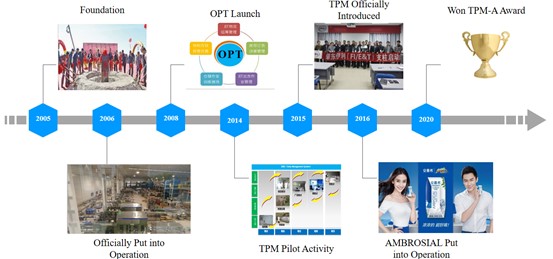

1.2.2 Production Process

Production process: Raw milk collection → milk clarifying → pasteurization → batching and testing → UHT sterilization → aseptic filling → packaging → storage → shipment. (9 major processes)

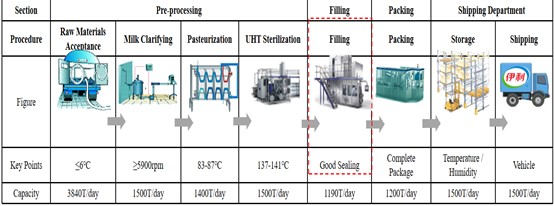

1.2.3 Equipment & Product

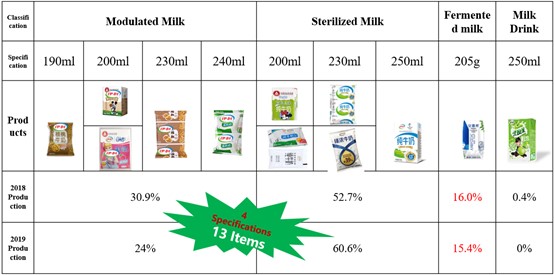

We have 35 sets of type A and B equipment (accounting for 13.89%). The average age of type A equipment is 7.5 years, the average age of type B equipment is 8 years, and the average age of type C equipment is 11.6 years. Our plant produces four major categories of products: modulated milk, sterilized milk, fermented milk and milk drinks. We produce 13 items with 9 specifications, of which the production of modulated milk and sterilized milk is more stable, and the production of fermented milk increases year by year.

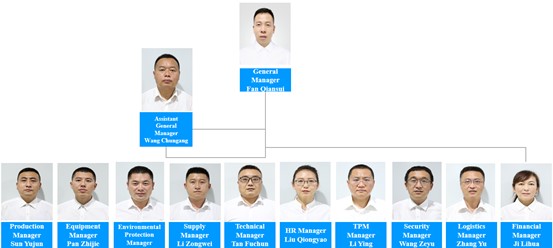

1.2.4 Plant Organization

Our plant consists of a general manager and 10 departments.

1.2.5 Employee Overview

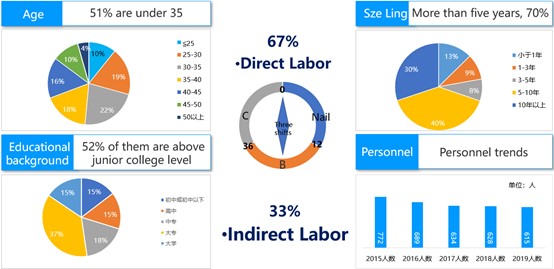

There are 615 employees in our plant, 51% of them are under 35 years old, 52% of them are with college degree or above, 70% of them are with more than 5 years of service, and 67% of them are direct laborers.

2. Milestones on the journey of Manufacturing Excellence

2.1 Reason for Introducing TPM

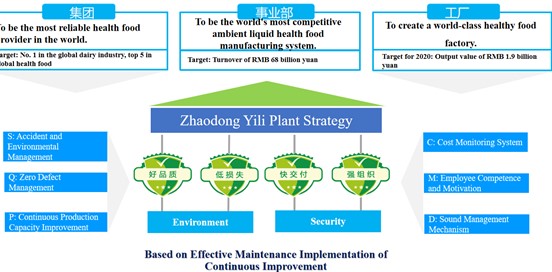

Yili Group’s vision is to be the most reliable health food provider in the world, so our plant must become a world-class health food manufacturing plant. We combined the factory SWOT analysis and formulated the factory strategy: Excellent Quality, Low Cost, Fast Delivery, Strong Organization. We introduced TPM in order to realize our strategy.

2.2 TPM Milestones

In 2014, our plant introduced TPM tools and methods and carried out team improvement activities to lay the foundation for TPM activities. In 2015, we officially introduced TPM. We first established the FI and E&T pillars. In 2016, we launched PM, AM, QM, SH and ENV pillar. The EM and OM pillars were launched in 2018. We plan to strive for the TPM Excellence Award Category A in 2020, as we have achieved steady improvement in plant performance and improved employee morale through the implementation of TPM activities.

3. Benefits Achieved

3.1 Tangible Results

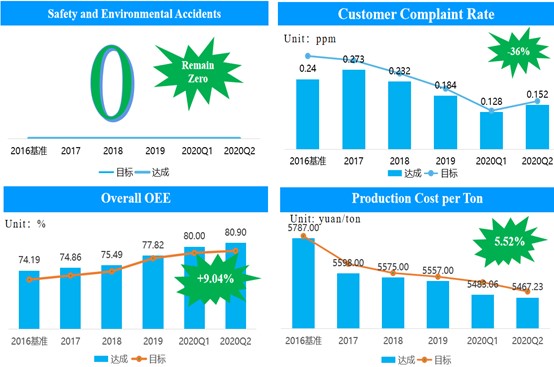

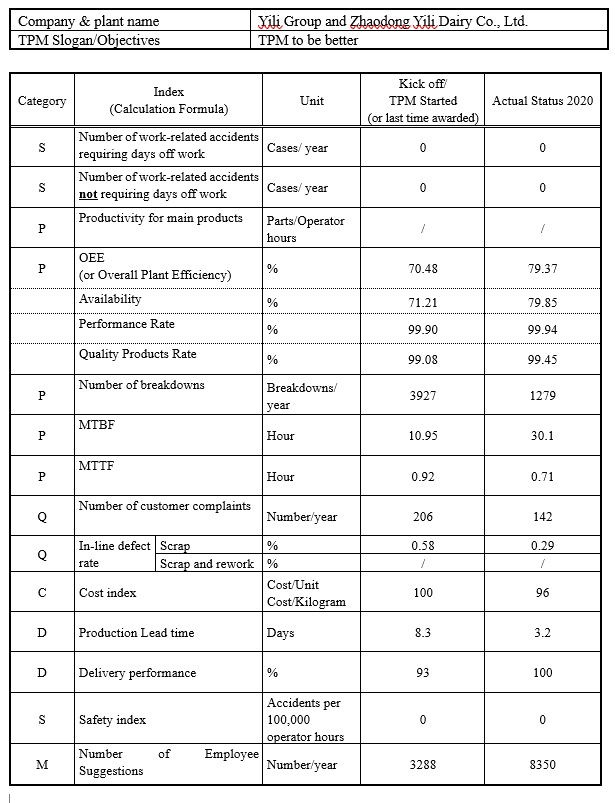

After years of TPM activities, our performance is improved significantly. The number of safety and environmental accidents remains zero; customer satisfaction, efficiency, output value, employee engagement, and technicians are trending better year by year.

3.2 Intangible Results

Collaboration awareness: collaboration between pillars has become closer, bringing greater cohesion in teams.

Personnel capacity: employees has developed the habit of systematic thinking and improved their problem-solving skills.

Morale improvement: the on-site production environment has been improved and employee morale has been boosted.

4. Key of our Manufacturing Excellence

Adopting TPM to manage our plant is agreed among our managers.

Integration of TPM activities with daily work, through DMS; focus on target achievement.

Comprehensive application of TPM methods for loss identification and continuous reduction.

Full participation in TPM improvement activities to promote the development of prevention habits and strengthen personnel capabilities.