Longyou Yili Dairy Co., Ltd.

| year | category | company | plant | area | industry | movie |

| 2020 | Category A | Longyou Yili Dairy Co., Ltd. | – | China | – | – |

Index.

1. Organization Profile

1.1 Company Profile

Yili Group was founded in 1956 and has gone through three stages of development. According to the newly released list of the world’s most valuable brands, Yili Group has become the third largest food company in the world and first in Asia. We add to our group vision the credo: Yili is Quality to ensure that we provide consumers with products that are 100% attentive, 100% safe and 100% healthy. Yili Group has 98 subsidiaries and has established R&D institutions and subsidiaries in Europe, North America and Oceania to achieve a global network. Yili Group’s total revenue for the first three quarters of 2020 was 73.770 billion yuan, an increase of 7.42%, and is expected to achieve revenue of 100 billion yuan for the year; Yili continues to rank first in the Asian dairy industry. Yili Group has a net profit of RMB 6.044 billion in the first three quarters of 2020 , ranking No.1 in the domestic market.

In 1956, we established the Cattle Breeding Cooperative Group in the Huymin District of Hohhot.

In 1993, we reformed our shareholding system and officially changed the company to Yili.

In 1996, Yili Group was listed on the stock exchange.

In 1996, Yili Group was listed on the stock exchange.

In 2008, Yili Group became a partner of Beijing Olympic Games.

In 2010, Yili Group became a partner of Shanghai World Expo.

In 2017, Yili Group became a partner of the Beijing Winter Olympic Games

In 2018, Yili Group became the world’s most valuable dairy brand.

1.2 Plant at Longyou

Longyou Yili is located in Longyou County, Quzhou City, Zhejiang Province. Longyou County is located in the western part of Zhejiang Province, Jinqu Basin, the topography of the south and north high, the central low, saddle-shaped. Longyou is known as the major juncture of four provinces, boasting developed roads, railroads, and waterways, so products can be quickly sold domestically. Our plant was officially put into operation in May 2015, covering a total area of 103,300 square meters, with an investment of RMB 550 million and an average daily output of 728 tons.

1.2.1 Brief History

Our e factory was laid in 2013 and put into production in 2015, TPM was introduced and basic improvement work was carried out in the same period. In 2016, our plant became the general warehouse supplier of ingredients for G20 summit and achieved good reputation. In order to meet the growing market consumption demand, we won Longyou County Quality Award in 2018. The second workshop of Longyou Yili was put into production in 2021.

1.2.2 Equipment and Products

The factory is equipped with the world’s advanced inspection instruments to meet the demand for inspection of raw milk, raw and auxiliary materials and finished products, while responding to the Group’s increasingly high food safety requirements.

The production process is divided into four stages: raw material collection, pre-processing, filling and packaging, and storage, all of which are produced with advanced equipment in the world. We have two product lines: fermented milk and milk drinks, with a total of 10 production lines and 8 items.

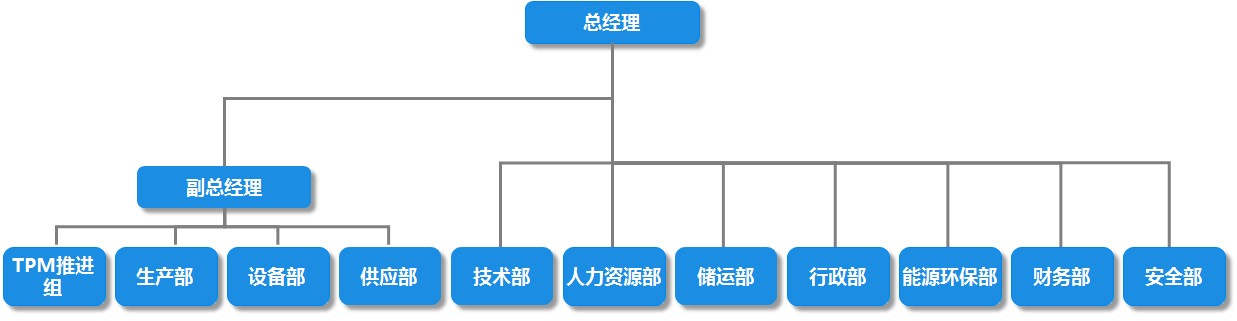

1.2.3Organization

There are 12 departments in our company, including TPM promotion team, production department, equipment department, supply department, etc.

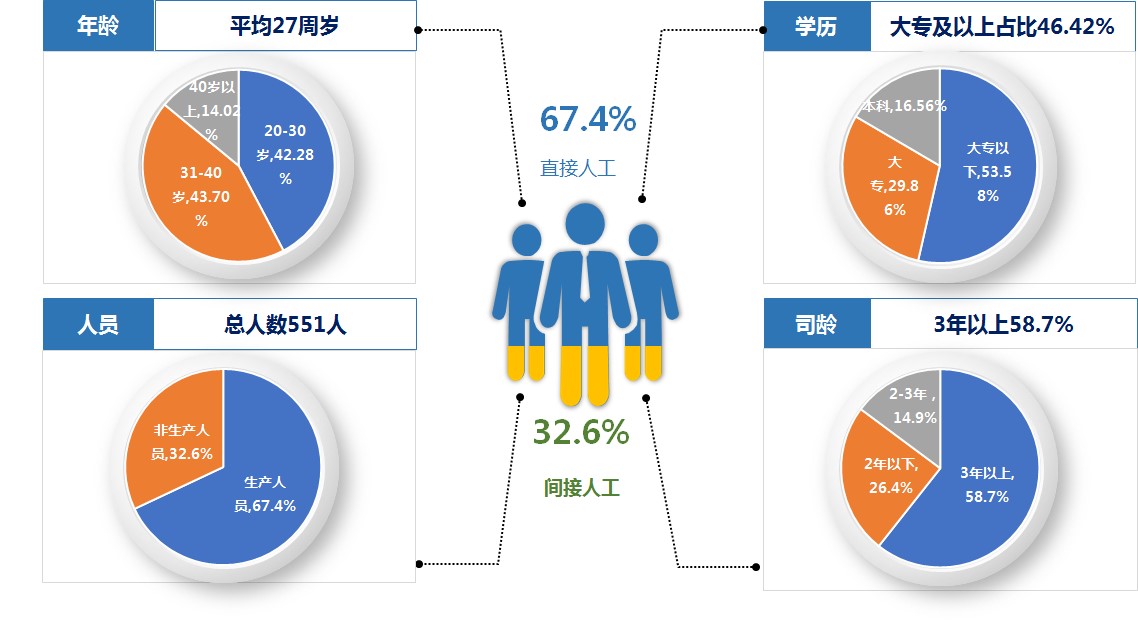

1.2.4 Employees

We have 551 employees, with an average age of 27, of which 46.42% are college degree or above, and 58.7% are over 3 years old. We have a cohesive team organization and a young team.

2. Milestones on the journey of Manufacturing Excellence

2.1 Reason for introducing TPM

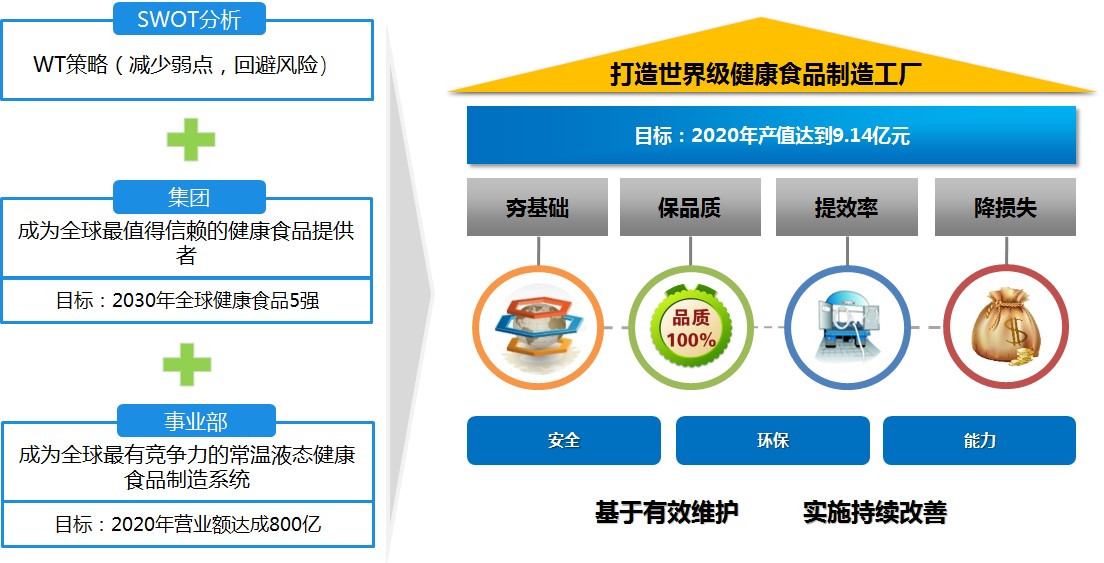

The vision of Yili Group is to Become World-class Healthy Food Factory. In order to support the the Group’s vision, the Liquid Milk Division set a turnover target of RMB 80 billion in 2020. In order to support the Liquid Milk Division’s target, our plant set the strategy of strengthening foundation, maintaining quality, improving efficiency and reducing losses through SWOT analysis.

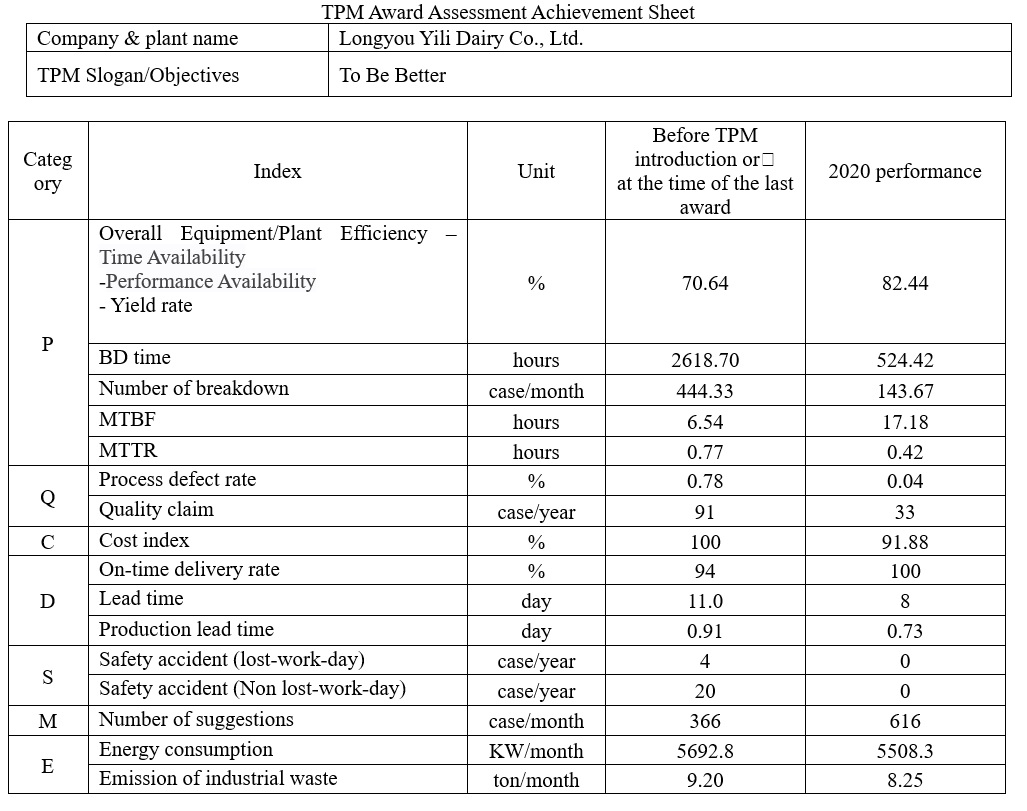

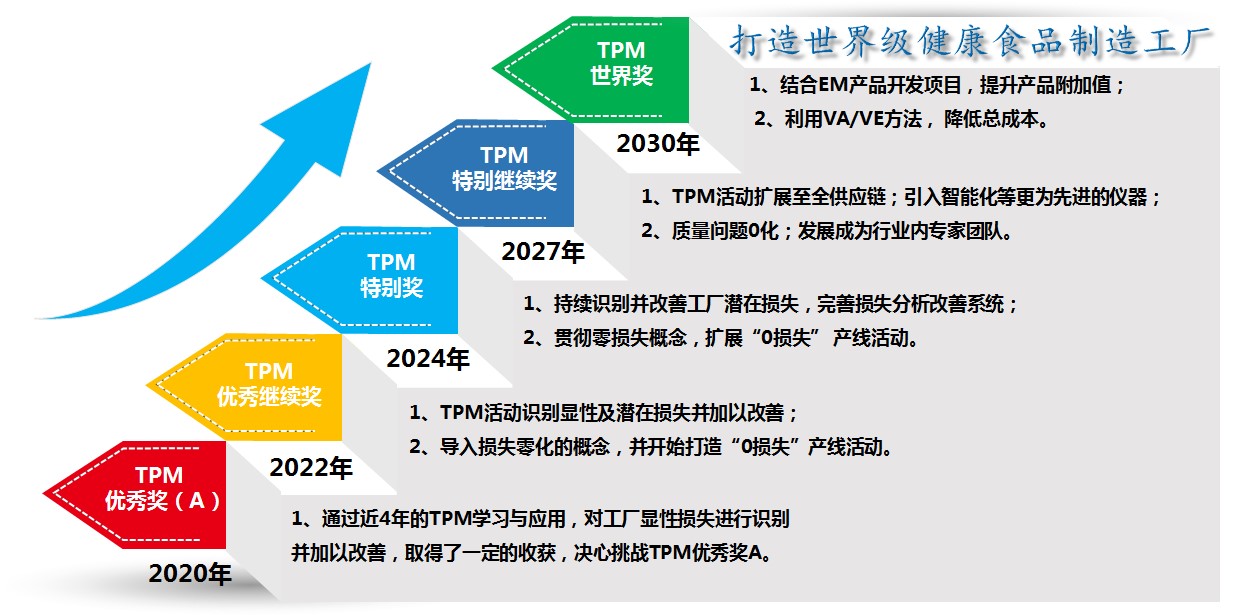

In 2015, our plant officially introduced TPM. We first established FI and E&T pillars, then successively introduced PM, AM, QM, SH, ENV, EM and OM pillars. Through TPM activities, our plant has achieved steady improvement in performance and improved employee morale, so we planned to strive for the TPM Excellence Award Category A in 2020.

3. Benefits Achieved

3.1 Tangible benefits: Improved performance

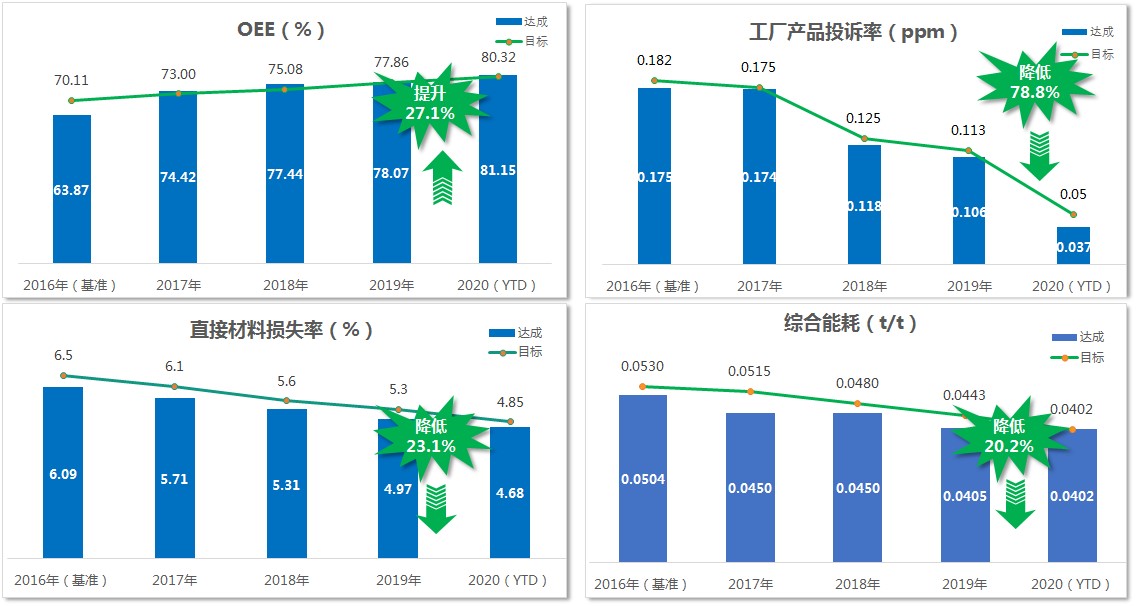

In 2020, in terms of efficiency, the plant OEE has been improved by 27.1%. In terms of quality, the plant product complaint rate has been reduced by 78.8%. And from the perspective of cost, the direct material loss rate has been reduced by 23.1% and the overall energy consumption reduced by 20.2%.

3.2 Intangible benefits: Improved performance

Collaboration awareness: collaboration between pillars has become closer, bringing greater cohesion in departments.

Personnel capacity: employees has developed the habit of systematic thinking and improved their problem-solving skills.

Morale improvement: the on-site production environment has been improved and employee morale has been boosted.

4. Key of our Manufacturing Excellence

4.1 Current State

We visualize all losses and pursue zero loss.

Our plant managers pays attention to and adheres to TPM, and collaboration between departments is closer.

Employees listen to customers’ needs and are 100% engaged, leading corporate transformation.

We enhance team cohesion and improve production operation and management through the integration of TPM improvement activities with daily work.

4.2 Future Plans

Next, we will identify the obvious and potential losses and make improvements, and we will continue to strive for various TPM awards to eventually achieve TPM World Class Manufacturing certification.