Klabin S.A. Angatuba – SP

| year | category | company | plant | area | industry | movie |

| 2020 | Category A | Klabin S.A. | Angatuba – SP | Brazil | – | – |

Index.

1. Organization Profile

Klabin is a producer of timber, packaging papers, cartonboard, corrugated boxes and sacks acting in domestic and international markets based in its sustainability principles for all activities related to its products and services. Founded 120 years ago, it has 23 units in Brazil and one in Argentina. It is the biggest paper producer, exporter and recycler of Brazil and worldwide leader in its acting segments. The company has a sales volume of 3.189 million tons showing gross revenue of R$ 4.3 billion (US$ 1.03 billion).

Angatuba Plant is responsible for 6% of this sales volume. The company has an annual capacity of 120 thousand tons of kraftliner marketable. The plant nowadays counts with forestry area of 5 thousand hectares of eucalyptus and 3 thousand hectares of preserved native forest.

fig. Application example of Klabin kraftliner paper.

The plant counts with 252 workers. Of this amount, 120 work in a rotational shifts journey assuring the constant production 24 hours by day. The Mill is composed of:

A) Wood preparation area that has a line with capacity of 45.8 ton/h of wood (eucalyptus). Every generated waste (around 1,000 ton/year) is recovering in the forest;

B) Cellulose production area that has three digesters with total capacity of 300 daily tons of cellulose;

C) Paper mill area that counts with one paper machine – PM14;

D) Chemical recovery area, which counts with an evaporation plant (30 ton H2O/h; 75 ton dry solids/day);

E) The utility production area counts with two power boilers with the capacity of 1.628 ton/day.

fig. Paper machine 14 building

2. Milestones on the journey of Manufacturing Excellence

During the analysis of the results in this plant in the year of 2004, improvement opportunities were observed. In that occasion, the external scene present demanding more product quality, as well as the as low rates of return over investment carried out. In the internal scene indicated the plant low efficiency, the continuous improvement culture did not exist. Facing this condition, we found in the TPM philosophy the strategy to develop our activities searching continuous improvement. In August/2004 was launched the TPM methodology with the name of “Klabin Superar” Program, which was an expansion of the program in the Monte Alegre Plant.

Beyond the constant certification maintenance ISO-9001 (2004), ISO-14001 (2004), OHSAS-18001 (2005) and FSC – Forest Stewardship Council (2006), several improvement projects were done in Angatuba Plant, among them emphasizing the Paper Machine nº 14 reform (2005) which expand the capacity from 78 to 100 thousand ton/year, and then in 2014 the factory goes through a new expansion project, this time to 130 thousand tons per year.

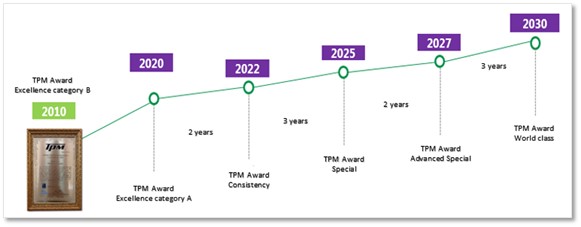

The “Klabin Superar” Program began with the consultancy of “Solving Éfeso” company in 2004, the first group of continuous improvement was graduated through the PKE – Process Kaizen Engineer course, OEE registers and analysis began through several KPIs and OPIs of the implanted Pillars gradually. In 2005 were launched five Pillars and improvement teams. In 2006, the program enters in the expansion phase with the launch of improvement teams and autonomous maintenance groups. In 2010, we achieved the “Award for Excellence – Category B”. In 2017, we present to all employees the program of awards until 2030, with the “Award for World-class TPM Achievement” as maximum target, going through all JIPM awards. Nowadays we have a support of PCM consult that helped us with preparation to the “Award for TPM Excellence – Category A”.

“Klabin Superar” Program next step is going on in the expansion phase in 2021 aiming intensify our continuous improvement activities and be ready to participate of the “Award for Excellence in Consistent TPM Commitment” in the year of 2022, with clear planning up to the world class award, as shown below.

3. Benefits Achieved

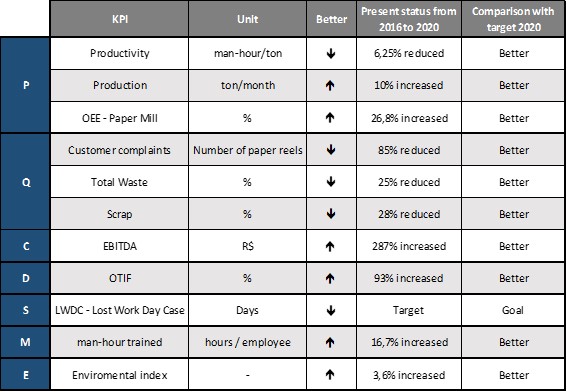

4. Key of our Manufacturing Excellence

Klabin establish as the first item of its sustainability policy the search for competitiveness quality aiming the sustainable improvement of the results, continuously perfecting the processes, products and services to meet our client expectation, workers, shareholders, community and suppliers. Based on this premise, Klabin has done the major volume of investments of its history.

The resources for production increasing capacity, factory improvement development in quality, productivity and environment place our plant among the biggest worldwide paper producer.

The industrial assets quality of this plant and the most modern production technologies utilization and the management contribute to the achievement of the excellence standards.

People are priority to us. We invest in a management system that allows us to do the follow up and the carrier development of our managers, succession plan base. The objective is the continuous improvement in the qualification and opportunities for our workers.

fig. Employees gathered after event in unit (Image taken before the COVID pandemic)

Our strategy for long term is remaining the competitiveness and the leadership based on the quality of our products, qualification of our workers and in the relationship with our clients and suppliers through continuous innovation and adequate costs.

To grow creating value in all we do, that is our compromise.