ADVIK HI-TECH PVT.LTD. CHAKAN.PUNE PLANT

| year | category | company | plant | area | industry | movie |

| 2020 | Category A | ADVIK HI-TECH PVT .LTD. | P-15 PLANT PUNE | India | – | – |

Index.

1. Organization Profile

ADVIK HI-TECH Private Limited (AHPL) is one of the India’s leading & global automotive component manufacturers. We have been catering to the growing needs of a number of domestic and overseas customers across four continents in the Design Development & Production of Engine, Transmission, Break & Emission Control Components from the past 20 years.

We Provide Custom Made solutions for our customer’s design, keeping in mind their needs and specifications. Our customer base includes leading automotive original equipment manufacturers in India, Europe, UK, US and the ASEAN region.

We are the preferred global supplier for a range of automotive components including Chain Tensioner, Oil Pumps, Fuel Cocks- Manual & Auto, Throttle Body, Decompression units, Water Pumps, Combi Brake System, Drum Gear Shifter, Starter Gears and many more.

ADVIK credit its success and growth to the areas of excellence, which include:

State-of-the-Art research and development center, which is recognized by Government of India.

Cellular manufacturing set-up for product engineering.

Most advanced machines with latest technology.

Manufacturing Excellence Through -TPM.

Testing and Metallurgical laboratory.

We have technical collaboration with German R&D company FMO Technologies (Trochocentric) GmbH for design, development & production of oil pump assemblies for passenger cars, commercial vehicles, stationary engines and transmissions systems. We are committed to provide world-class products to our customers in an effort to create a global footprint in world market.

– Plant at Pune Location

Pune plant is the 15th plant of ADVIK HI-TECH PVT. LTD. It is a manufacturing facility established in 2015 and it is located at Sector -Plot No. B-5, Chakan Industrial Area, Phase-II, Village – Vasuli, Tal – Khed, Dist – Pune – 410 501

Pune Plant Manufactures Oil pumps, Tensioners, Fuel cocks, Drum Gear shifter, Throttle body, Bracket, Lever Starter Gear and De-comp & and supplying to all OEM of two wheeler manufacturers.

– Product Capacity

Engine Components

Oil Pump – (# Globally Leading with 17 Million/year & 28% market share)

Water Pump -(5 Million/year)

Tensioners – (# Globally Leading with 17 Million/year & 35% market share)

Decompression Assembly – (4 Million/year)

Fuel Cock (Auto & Manual) – (6 Million/year)

Transmission

Drum Gear Shifter – (3 Million/year)

Starter Gear – (3 Million/year)

Brake- Combined Braking System – (# Globally Leading with 5 Million/year)

Emission Control

Air Secondary Valve (ASV) / Secondary Air Injection (SAI) – (2 Million/year)

Purge Valve & Reed Valve – (5 Million/year)

2. Milestones on the journey of Manufacturing Excellence

ADVIK in line with philosophy of the company and the group has always been best in its Product Quality

And Quality is Never ending Journey in ADVIK, which strives to Continuously improve all the key performance parameters, Major challenges during this journey including improve the equipment reliability & People competencies at all levels.

In today competitive scenario, to achieve business excellence in all spheres, its need to team work & TPM is one of the best Manufacturing Practice followed by most of the world successful companies

With philosophy and commitment being the guided force of ADVIK PUNE Location & also undertook Implementation of TPM (Total Productive Maintenance) as a Company Mission in 2016.

TPM journey drives ADVIK towards continuously enhancing turnover, increasing profitability and constantly reducing the production costs by eliminating all losses due to BAD (Breakdowns, Accidents, Defects).

TPM Journey started in 2015 with Manager Model Machine, demonstrated by team of competent and committed managers to the workers, ADVIK Pune Plant Launched TPM Activities 21st March 2017 with formal kick of ceremony held in the Presence of Valuable Customers Bajaj, Honda, TVS & Yamaha & Top officials of the Organisation.

For the Foundation of TPM 5S Implementation, Employee Suggestion scheme (Digital Plat form), Kaizen Katta, Circle Formation & Circle competition, success celebration, PIP (Productivity Improvement Projects) are some Initiatives in system in Front and PIP is the Major initiative towards the Productivity enhancement

Apart from the Other achievements following are some laurels won by the ADVIK Pune Plant since TPM Launch

2016-Countless Dreamer award by HONDA

2016-Consistently High Quality Performer Award-Maruti Suzuki

2017- Winner –Manufacturing India Award CII

2017- 2 wheeler Cost Down award- Maruti Suzuki

2018- BAL TPM Excellence Award

2019-Best Kaizen Award, Best SMED Award -CII

2020-Green Factory Buildings Rating System Award –Gold –IGBC (Indian Green Building Council)

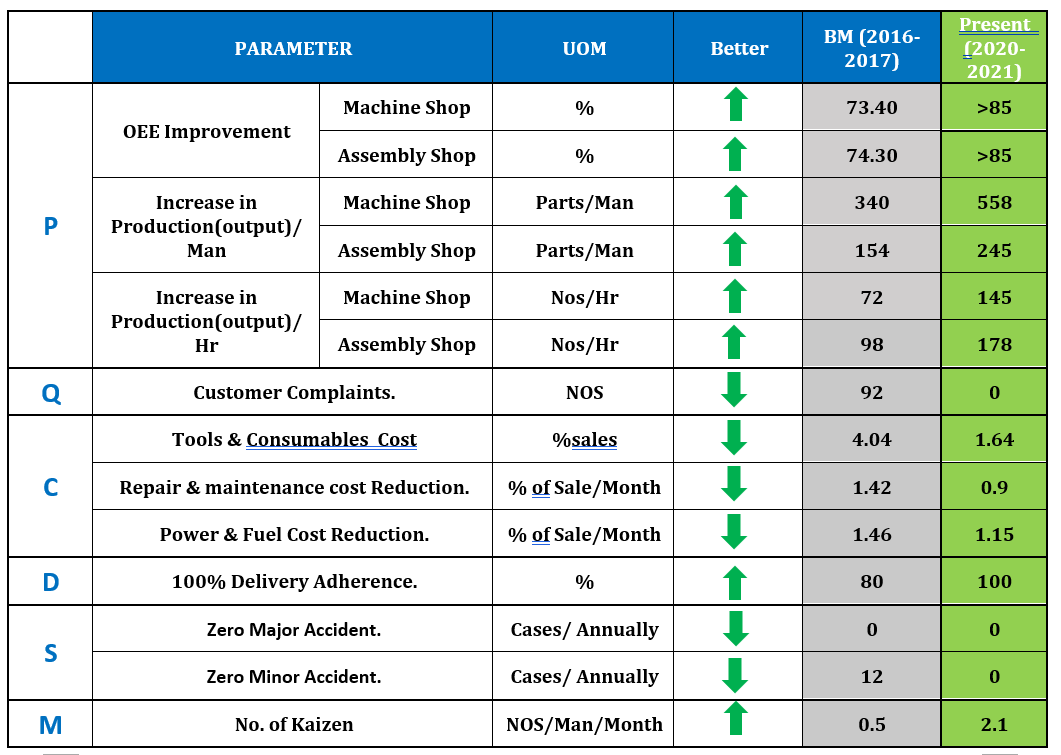

3. Benefits Achieved

TPM Implementation at ADVIK Group Companies not only Helped to in Business results but also brought drastic change in Organisation Culture and Create the Ownership in Employees, Increase in Employee Suggestion is one of the sample evident for involvement of highly motivated employees and as well as the Some Tangible Benefit we get from the TPM Implementation as following –Key business results in terms of PQCDSM.

Employee Involvement and Motivation, some Intangible Benefits

• Enhanced Teamwork approach for continuous improvement activities through TPM.

• Enhanced employee Morale due to focus on Zero Customer Complaints, Zero in process defects, Zero breakdowns and Accident.

• Employees have Sense of Pride so started thinking Widely and Deeply in their areas / section to improve from existing condition to next level.

• Employees are now work as per the Flexibility of requirement and open for any changes.

• Sustenance of Improvements done by the operators.

• Enhanced operator ownership of equipment with understanding on importance of maintaining basic condition i.e. “I Operate, I Maintain, I Control”.

• Repeated failures / defect are not happening due to corrective maintenance & development of Analytical Capability.

4. Key of our Manufacturing Excellence

The key of our Manufacturing excellence in line with Continuous Improvement activities and Review Mechanism for the results meet the Strategic Performance & Business Results.

Future Plan

• Challenge Consistency Award in 2024

• For ZERO Loss-Moe Kaizens to Implement

• Implement the TPM at Supplier End at New Initiative from ADVIK-Daisha Program