BRIGHT DAIRY & FOOD CO.,LTD Wuhan Bright Dairy Co.,Ltd

| year | category | company | plant | area | industry | movie |

| 2020 | Consistent | Bright Dairy & Food Co., Ltd. | Wuhan Bright Dairy Co., Ltd | China | – | – |

Index.

1. Organization Profile

Wuhan Bright Dairy Co., Ltd belongs to Bright Dairy & Food Co., Ltd.

Bright Dairy & Food Co., Ltd was founded in 1996. It is the third largest dairy enterprise in China which is specializing in producing and selling all kinds of dairy products.

Wuhan Bright Dairy Co., Ltd. is a medium-sized dairy processing enterprise based on production of fresh-keeping dairy products

The company is located in No.1 Zhang bai Road Dongxihu District, Wuhan city, Hubei Province, P.R. China. It is a joint venture found by the Bright Dairy & Food Co., Ltd and the Wuhan Dongxihu Haikou Dairy factory in 1999.

Company has a registered capital of 190 million RMB and an annual capacity of 198 thousand tons, with a total number of 470 people.

The product categories cover 5 series including Fresh milk, E+yogurt, Jianneng yogurt, Changyou yogurt and Plant vigour drinks. Then the series are subdividid into 76 varieties and specifications of products.

The products are distributed in central region and southwest of China. Marketing channels give priority to modern business super, boutique and home delivery, restaurants and group purchase are complements, and combining with vending machines and E-commerces.

Market share of central China: fresh milk accounts for 80%, fresh yogurt accounts for 38%, and lactic acid bacteria beverage accounts for 27%.

2. Milestones on the journey of Manufacturing Excellence

Established in October 1999, the company produced bottled milk, packaged milk, yogurt with plastic cup and industrial milk powder with a daily output less than 20 tons.

From 2000 to 2008, it has obsoleted glass bottled packaging and added new production lines in term of paper cups, buckets, PrePack and Ecolean. It obtained ISO9001 quality system certification in 2002, then awarded HACCP certification in 2005.

In 2009-2010, in order to solve process bottlenecks, it imported 3 high-speed shrink packing machines and plastic bottle production line. A production scale of 200 tons per day was formed, and it also obtained GMP certification in the same year.

From 2010 to 2013, the company carried out activities —reducing cost and increasing efficiency. Obsoleting milk powder equipments and PrePack products, developing Changyou drinks and introducing automatic packaging equipments increased the production capacity to 300 tons per day.

In 2012, it won the honor of Cleaner Production Enterprises and the National Safety Production Standardization Enterprise Level 2.

TPM was introduced in 2014.The improvement activities were carried out to eliminate production line bottlenecks. The company obtained the Integrity Management System certification.

KICK OFF was held in February 2015 to implement TPM. The company won the first prize in the annual Bright Dairy Food Safety Chain Management Quality Review, Management Innovation award and TPM Projects Excellent Factory.

In 2016, the TPM activity developed horizontally. The TPM team obtained the “Worker Pioneer” in the Dongxihu District.In 2016, TPM activities in full swing, the TPM team won the Dongxihu Area ‘workers vanguard title’.

In August 2017, the factory certified by the FSSC22000 system, and the management level of the food safety system was improved.

In 2018, the company has carried out the activities of ranch, package material supplier guidance and market visit; WCM exchange activities, The company has won the top 20 tax paying enterprises in local manufacturing industry;

In 2019, the construction of new Dojo, supply chain activities and comprehensive cost improvement activities have been carried out;

In 2020, new factory system and TPM activities of new factory are included;

3. Benefits Achieved

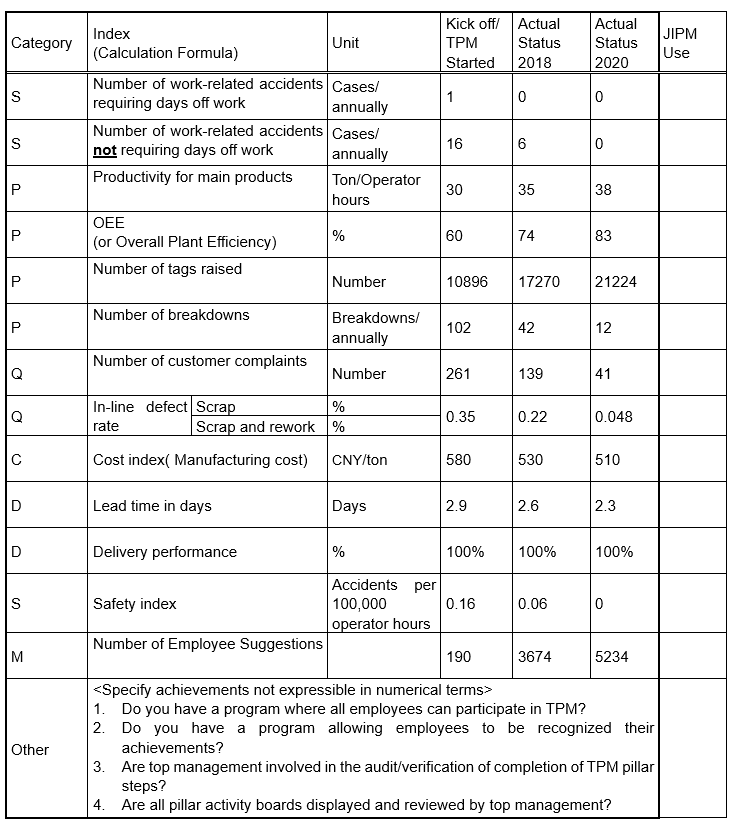

Compared with 2017, during the 3 years (2018-2020) of TPM activities carried out, the annual output and profit increased by 19.8% and 50% respectively. Output/ Input =8.5/1.

The Loss rate decreased by 77%; AB class Overall Equipment Effectiveness(OEE) increased by 38%; the Complaint rate declined 87%; product manufacturing costs per tons falled 5%; delivery rate was 100%; the significant complaint was 0; deficient manufacturing procedure decreased 85%; the major events of injuries and suspension of business were 0; red medicine events decreased by 75%.

The improvement consciousness and skills of all staff were improved. Workplace became safe and healthy, teamwork was getting more friendly and smooth and employee satisfaction was enhanced. TPM activities were unanimously recognized.

In 2019, the operating revenue of Wuhan Bright Dairy Co., Ltd. only accounts for 3.81%, but the realized profit is 100 million yuan, accounting for 14.66% of Bright Dairy, ranking second among 18 factories.

The net profit margin is 11.6%, the highest in the group.

With the construction and operation of the new plant, its future contribution will continue to increase, and it will play a greater regional advantage;

The market share of fresh-keeping products in Hubei Province is 80%;

Through the development of WCM activities, combined with the needs of new factories in the future, talents are constantly introduced, and the number of college and undergraduate degree personnel increases by 5%;

With the improvement of skills, the degree of automation is improved, and the number of production personnel is reduced by 6%;

Under the guidance of sustainable development and becoming the most competitive benchmark

factory in China’s dairy industry, it formulates TPM activity policy and creates efficient factory operation system; The new factory will become a modern dairy enterprise with high yield and high efficiency, green environmental protection, intelligent manufacturing, industrial tourism and other functions.

4. Key of our Manufacturing Excellence

Carrying on maintaining and improving activities continuously and using the method of PDCA to keep the virtuous cycle of work made the factory realize the operational objectives.

1. The factory manager leading TPM Promotion Committee integrated the functions of the 8 pillars and every department. Coordination meetings and small group activities which focused on the KMI of the plant and KPI of the departments were regularly held.

2. Aiming at 0 complaint to carry out the AM-PM-QM + EM Trinitarian improvement activities which gave priority to QM pillar and improve the FSSC system.

3. In the AM1-7step, the 7 steps activity of food safety was an important part to carry on. Taking advantage of the food safety map was the way to control the food safety risks.

4. Taking active events as the driver to carry out various competitions and evaluation activities in order to maintain and improve the enthusiasm of all members participating in the TPM activities.

5. Mock-up teaching way improved the effect of training, cultivated a large number of professionals and expanded the promotion access for staff.