BRIGHT DAIRY & FOOD CO., LTD. Bright Dairy (Dezhou) Co., Ltd.

| year | category | company | plant | area | industry | movie |

|---|---|---|---|---|---|---|

| 2020 | Consistent | Bright Dairy & Food Co., Ltd. | Bright Dairy (Dezhou) Co., Ltd. | China | – | – |

Index.

1. Organization Profile

Bright dairy & food Co., Ltd. is a diversified ownership shareholding listed company composed by state owned asset and social public capital. It’s business covers the development, production and sales of milk and dairy product, and also includes milk cow feeding, cultivation, logistics, nutrition and health food development, production and sales these kind of business. Until now, bright dairy & food is one of the largest domestic enterprise in dairy products production and sales.

The business of bright dairy & food started in 1911, and in 2003, the company changed its name to Bright Dairy & Food Co., Ltd. In 2013, after taken over the Synlait Milk, bright dairy & food was successful listing in New Zealand marketing. The company is the first domestic dairy enterprise with such kind of experience. It creates a more international Bright Dairy.

– Bright Dairy (Dezhou) Co., Ltd. Introduction

Bright Dairy (Dezhou) Co., Ltd. is one of the 18 internal factories of Bright Dairy & Food Co., Ltd. It locates in Dezhou city, the northwest of Shandong Province. Dezhou city is an inland agricultural city with rich resources and kind people. It is about 318 kilometers to Beijing. The factory is located in Nr. 2157, Jinghua Road with 70 mu land, the standard workshop with 23,389 square meters was built up. The factory was up and running in Sep 16th, 2001. By 2020, the company will have assets of 300 million yuan and sales of 763 million yuan. By December 2020, the factory has 586 employees. The factory is under the general manager responsibility system and has seven departments including production department and quality department. The factory has 47 sets of AB equipment, which are also the main equipment to carry out zero failure. ABC is reclassified and maintenance countermeasures are adjusted according to the equipment status every year.

The factory products cover 14 varieties of sterilized milk, prepared milk, normal temperature yogurt and milk beverage. Fermented milk and sterilized milk are the main products,As shown in the figure below:

2. Milestones on the journey of Manufacturing Excellence

The vision of Dezhou factory is to be the world class dairy manufacturing plant with the first choice by consumers. With this vision, Dezhou factory tried to use some TPM tools to improve the performance in 2012, and got good performance. To expand the improvement performance and realize the vision, the factory decided to fully introduce TPM management system into the factory in January 2014 to help the factory realize its strategy and vision. Through three years of efforts, in November 2017, we challenged the success of TPM Excellence Award and launched a challenge to the excellence continuing award. The scope of activities extended from factories to pastures, logistics and other areas. The focus of activities changed from systematization to refinement, and the system and foundation established before were continuously implemented and optimized. Following is the main events of the factory development:

Sep. 2001, Factory up and running

Sep. 2002, Increased the capital and stockholding, and yearly output reached 10,000 tons

Apr. 2004, Passed ISO9000 & HACCP certification

Sep. 2010, Momchilovtsi TPA package started to produce in Dezhou factory

Dec. 2012, Awarded certificate of “Ability verification qualified laboratory” by CNCA

Dec. 2013, Reached yearly output 140,000 tons of room temperature yogurt after 3rd phrase.

Jan. 2014, Launched TPM management system

Oct. 2014, TPM kick off meeting

Mar. 2015, Launched the credit management system

Dec. 2016, Bright Dairy 2016 TPM outstanding factory

Dec. 2016, The Central Laboratory of the factory has passed the national CNAS certification

Nov. 2017, TPM Excellence award,Category B

Dec. 2018, Pass FSSC22000 certification

Dec.2019, No.1 in 2019 Guangming dairy quality evaluation

Dec.2020, No.1 in 2020 Guangming dairy quality evaluation

2020, Award for Excellence in Consistent TPM Commitment

3. Benefits Achieved

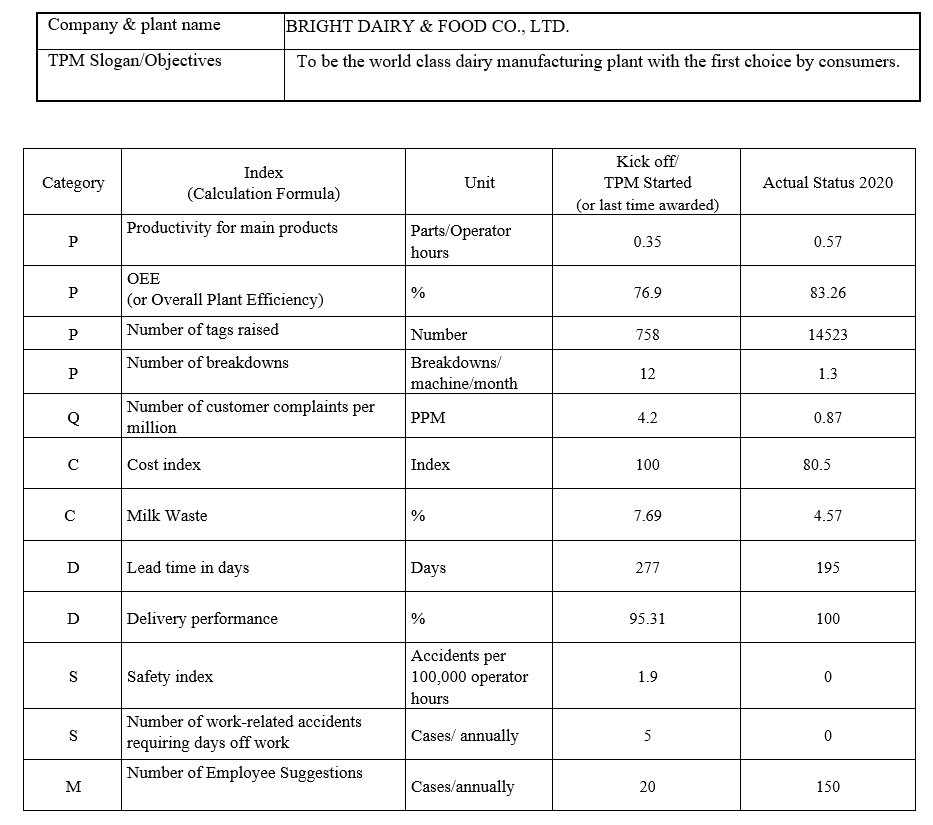

Since we launched the TPM management system from Jan. 2014, the performance keeps improving. Compared with 2013, the key KPI of the factory has been improved. The OEE of key equipment is increased by 18.94%, the rate of quality complain is decreased by 79.53%, the milk loss is decreased by 63.44%.Employees actively participate in the management of the factory,at present, 100% of the employees of the whole factory participate in the continuous improvement activities of the factory, and the employees have put forward 11504 rationalization suggestions. Through the deepening of TPM excellent continuous Award activities, the indicators of the factory have been improved, at the same time, the culture of full participation in enterprise management has been created, and the working environment of the employees is more safe and comfortable. The staff’s structure and concept of cost improvement have been improved, and the cost per ton has been continuously reduced. By carrying out zero defect activities, the quality awareness of employees was improved, the product quality was improved, and the food safety risk was reduced.After launched TPM system, the shop floor and equipments keep in order, and each department is in a closer relationship with more cooperation and communication. Staff morale and company image are greatly improved.

4. Key of our Manufacturing Excellence

It is the vision of Dezhou factory to become a world-class dairy manufacturing factory preferred by customers. It is the goal of Dezhou factory to become a comprehensive performance benchmark factory within the group. It is also a commitment to the organization and a reflection of its own value. The firm determination of the senior leaders of the factory to implement TPM makes our faith never waver. We always adhere to the TPM tool as the starting point, and continue to carry out various improvement activities Safety management (production safety, quality safety, environmental safety), cost reduction, staff skills improvement and improvement of the atmosphere have made certain achievements. Through continuous staff training and self maintenance activities, we have a strong staff foundation for the implementation of TPM. Every Bright Dairy employee maintains a continuous improvement mentality and actively participates in the daily TPM improvement activities to contribute to the continuous improvement of factory performance and ensure the comprehensive promotion of TPM in the factory.