BRIGHT DAIRY & FOOD CO., LTD. Bright dairy (Jingyang) Co., Ltd.

| year | category | company | plant | area | industry | movie |

| 2020 | Category B | Bright dairy (Jingyang) Co., Ltd. | – | China | – | – |

Index.

1. Organization Profile

1.1 Company profile

Bright Dairy Co., Ltd. was founded in 1996, its sales volume is RMB 20.9 billion in 2018, the market share is 20% in China, the asset is RMB 16.57 billion. The Bright Dairy (Jingyang) Co., Ltd. is one of the 17 subordinate factories of Bright Dairy Co., Ltd in China.

1.2 Factory profile

1.2.1 Profile

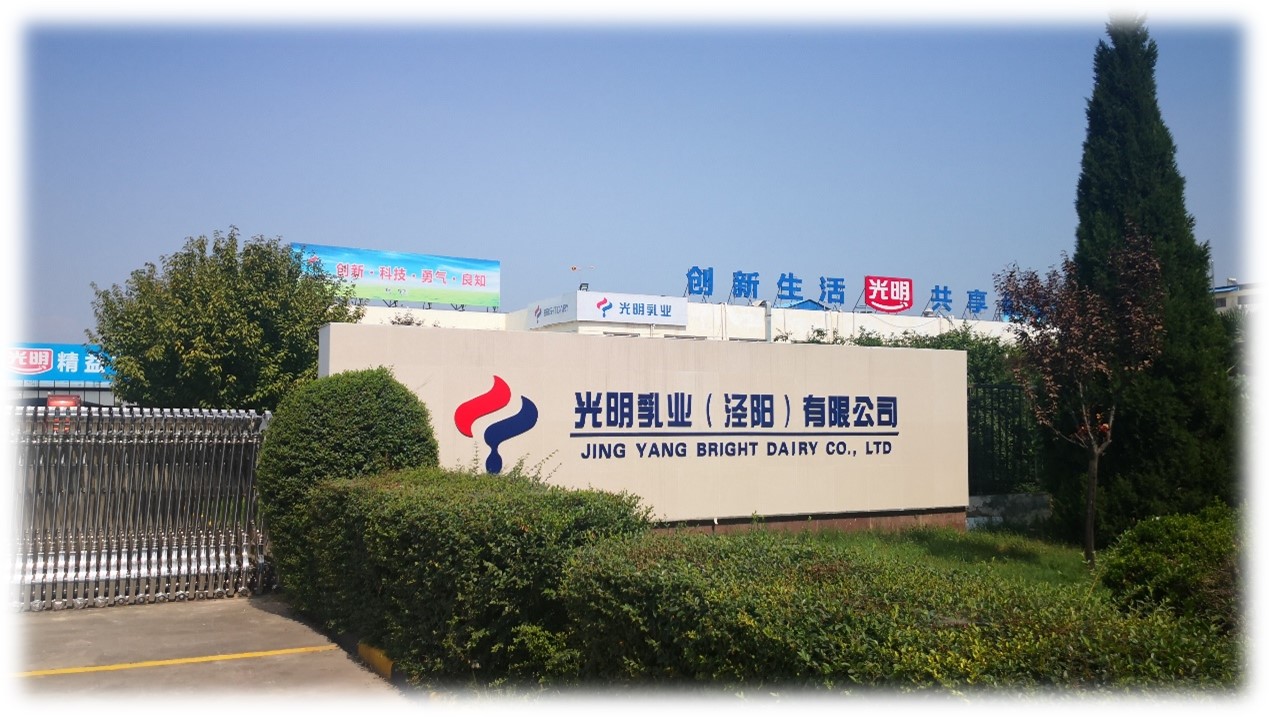

Bright Dairy (Jingyang) Co., Ltd. is located in Jingyang County, Xi’an City, Shaanxi Province, it is the central geography point of China. It was found on December 24, 2001 and started production on July 19, 2002.

The company is 20715.70 square meters, the construction area is 8409.64 square meters, the main workshop is 7,600 square meters. There are 275 employees, 27 technicians, and 12 management staff.

The factory area is centered on the main workshop, and the raw & auxiliary materials and finish-goods warehouse, inspection office, hardware warehouse, power distribution room, refrigeration room, boiler room, sewage treatment equipment, etc. are distributed around, they are independent and reasonably distributed to ensure the safe and efficient production process.

1.2.2 Journey

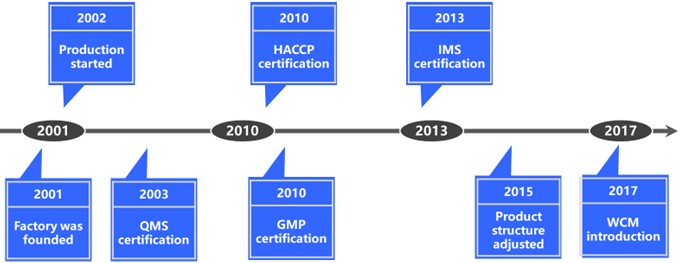

Factory was founded in 2001;

Production was started in 2002;

Passed the quality management system (QMS) certification in 2003;

Passed the certification of hazard analysis and critical control point system (HACCP) and good manufacturing practice system (GMP) for dairy products in 2010;

Passed the integrity management system (IMS) certification in 2013;

Product structure adjusted in 2015, mainly producing student milk products;

Introduced the WCM in August 2017.

1.3 Process

Process: Milk inspection→ pasteurization → Formulation → UHT sterilization → aseptic filling → packing

1.4 Organization

1.4.1 Organization structure

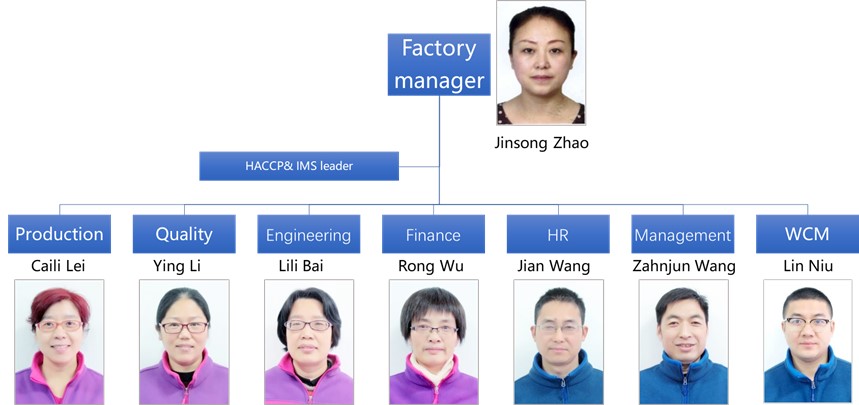

The organizational structure of the Jingyang is led by Jinsong Zhao who is the factory manager, the leader of the food safety and integrity management team is the assistant. There are six departments: HR & administration, Quality, Production, Engineering equipment, Finance, management. The WCM belongs to the management department. The factory has 275 employees now, including 154 formal employees and 121 temporary workers.

1.4.2 Employee structure

The 51.46% of staff is the production according to the position in the factory. The 22.91% of staff has a college degree or above according to the proportion of the education qualifications; there are 128 staffs are from the age of 41 to 50 according to the age distribution; 78 staffs have worked for 5-10 years in the factory.

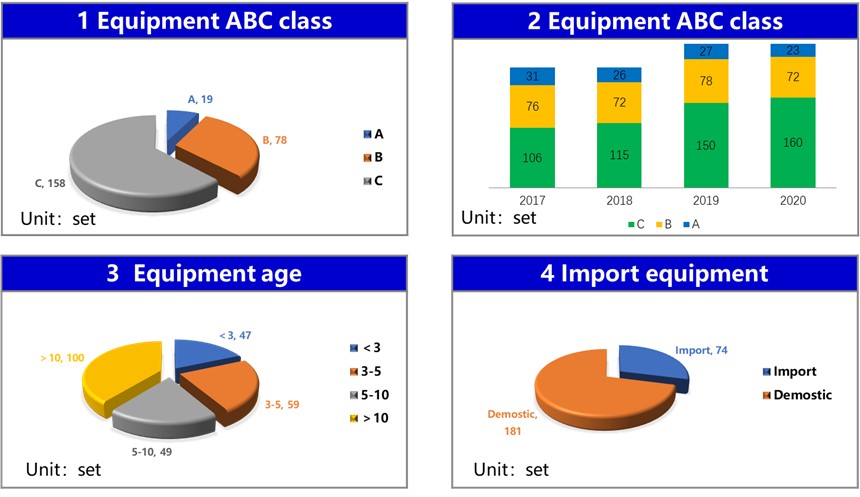

1.4.3 Equipment

When the factory introduced TPM in 2017, there were 31 class-A equipment, 76 class-B equipment, and 106 class-C equipment. In 2020, there are 23 class-A equipment, 72 class-B equipment, and 160 class-C equipment. There are 47 equipment under 3 years old, and 100 equipment over 10 years old. There are 181 domestic equipment and 74 imported equipment.

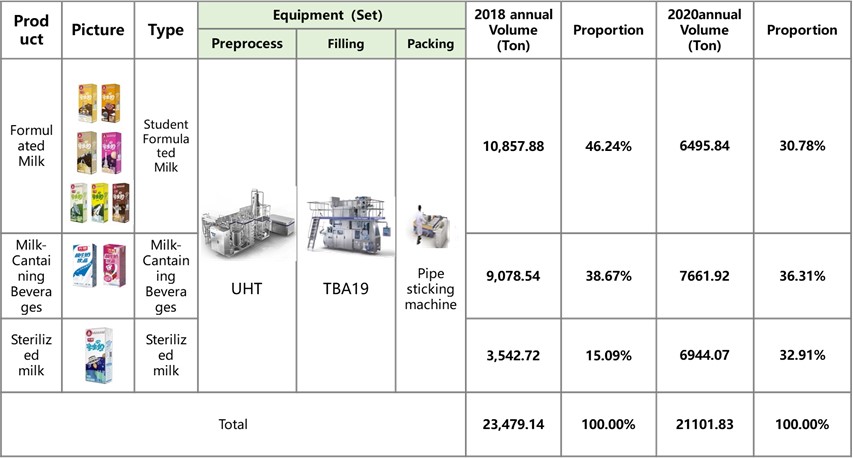

1.5 Product

The products of Bright Dairy (Jingyang) Co., Ltd.’s mainly include three types of products: formulated milk, milk-containing beverages and sterilized milk. According to the 2020 volume analysis, the proportion of formulated milk is 30.78%, the proportion of milk-containing beverages is 36.31%, and the proportion of sterilized milk is 32.91%.

2. Milestones on the journey of Manufacturing Excellence

2.1 Reason for adopting TPM

The TPM vision of the Jingyang factory is to build a world-class dairy manufacturing plant in the Northwest.

In order to realize this vision, the strategies are: low cost, high efficiency, perfect quality, absolute safety, and high education. These strategies are completed by the six pillars: FI, PM, AM, QM, SHE, E&T. Each pillar measures the work results through different key management indicators and key performance indicators.

2.2 Milestone on the Journey of Manufacturing Excellence

In August 2017, the Jingyang factory introduced TPM and began TPM basic training officially. And officially launched 7 pilot improvement teams, including efficiency, training processes, equipment failures, AM and 5S.

Within five months of the official introduction of the TPM, the FI, PM, AM, QM, E & T and SHE pillars have been established and started to operate. We plan to achieve the TPM Excellence Award in 2020.

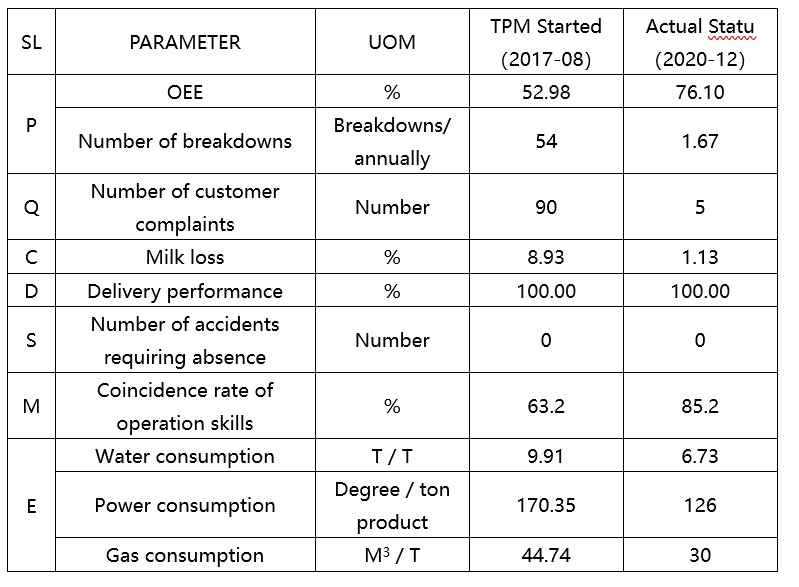

3. Benefits Achieved

TPM as the world’s advanced continuous improvement system, through the pursuit of zero loss, full participation to achieve continuous improvement. Therefore, we choose TPM as the tool to realize the plant strategy. From August 2017 to September 2020, the factory officially introduced TPM and achieved the following results:

4. Key of our Manufacturing Excellence

1. TPM activities are closely integrated with plant management.

2. The communication and cooperation of departments and pillars are Strengthen.

3. Continuous improvement.

4. All employees are engaged in the TPM activities.